Shenzhen Tongcheng Automation Equipment Co., Ltd

QQ:443231019

Phone:0755-33199429

Cell phone:13823266293 Mr.Rao

18128639712 Mr.Chen

Email:

472233169@qq.com Mr.Rao

1249785244@qq.com Mr.Chen

Ministry of Foreign Trade:

Lily Mob/Wechat/WhatsAPP

/Facebook/X : +86 18772968620

Email : 2413092183@qq.com

Website:www.toolcen.com

Factory Address: No.4 Rongzhong Road, Chencun Community, Humen Town, Dongguan City, Guangdong Province, China.

High speed manipulator meets more flexible automation applications

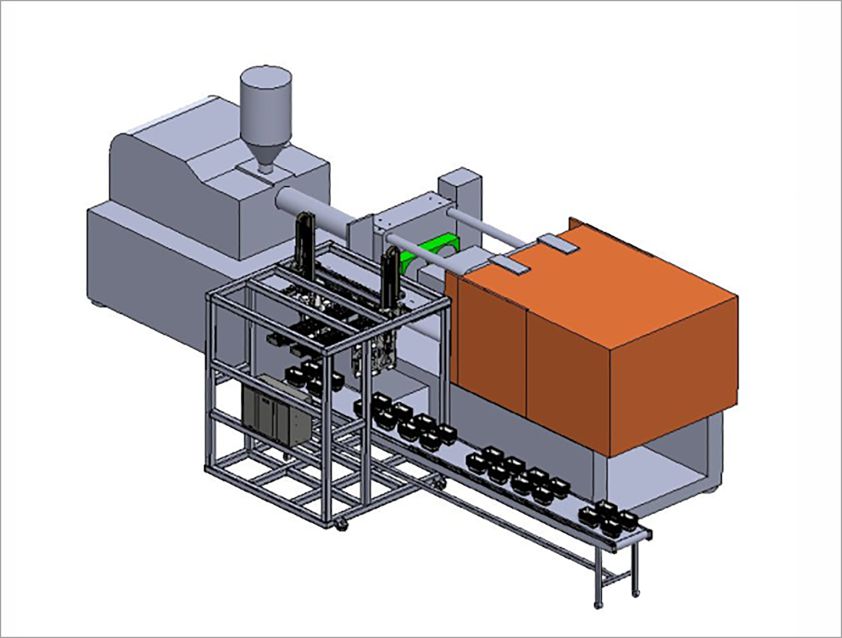

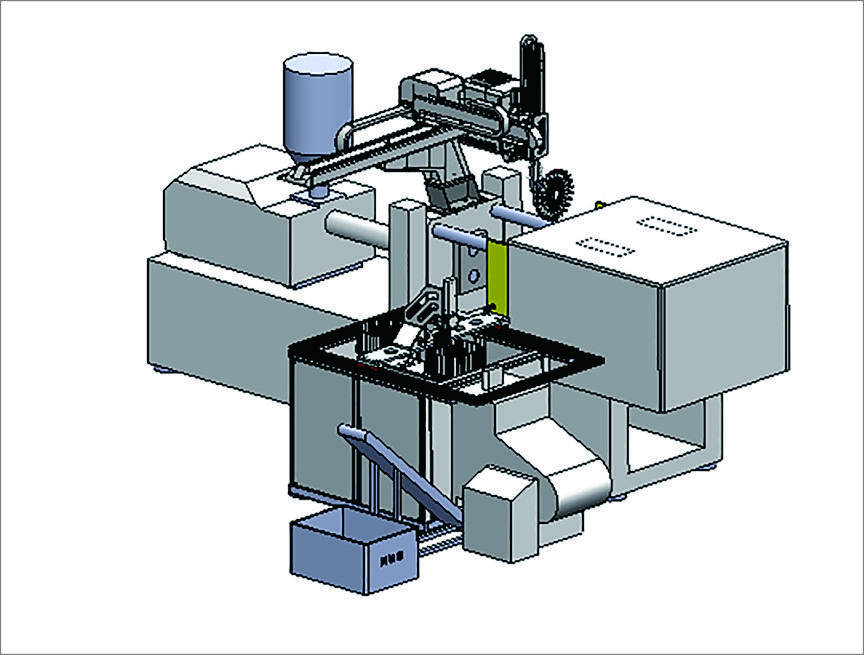

German machine manufacturer Klaus Maffei (KraussMaffei) in the market on the secondary locking force of the injection molding machine automation applications, based on the existing LR series is based on the development of LRX linear robot series, to meet user demand for flexibility.

The new LRX 250 (payload 25kg) fills the gap between the previous LRX 150 (payload 15kg) and LR 300 (payload 30kg). Other new products, such as LRX 350 (payload 35kg), have more options for users. The user can choose from 7 kinds of LRX payload specifications. The smallest linear manipulator is LRX 50 with a payload of 5kg, and the maximum payload is LRX 1000 of 100kg. The new LRX 250 and LRX 350 expand the range of medium payload.

In addition, Claus Maffei's engineers also expanded the new LRX series configuration selection, compared with the LR series, users have more options.

LRX has 3 down area standard layout: on the longitudinal axis of the machine, on the operator side or on the non operator side. The control unit is integrated on the Z axis of the manipulator, so the LRX manipulator is easy to operate, save space, and leave more space for production. All axes are moving at the same time, which can shorten the period time and improve the flexibility. Because of the absolute position measurement function, the manipulator can identify its precise position at any time and further save time.