Shenzhen Tongcheng Automation Equipment Co., Ltd

QQ:443231019

Phone:0755-33199429

Cell phone:13823266293 Mr.Rao

18128639712 Mr.Chen

Email:

472233169@qq.com Mr.Rao

1249785244@qq.com Mr.Chen

Ministry of Foreign Trade:

Lily Mob/Wechat/WhatsAPP

/Facebook/X : +86 18772968620

Email : 2413092183@qq.com

Website:www.toolcen.com

Factory Address: No.4 Rongzhong Road, Chencun Community, Humen Town, Dongguan City, Guangdong Province, China.

The role of injection molding manipulator is becoming more and more important in injection production

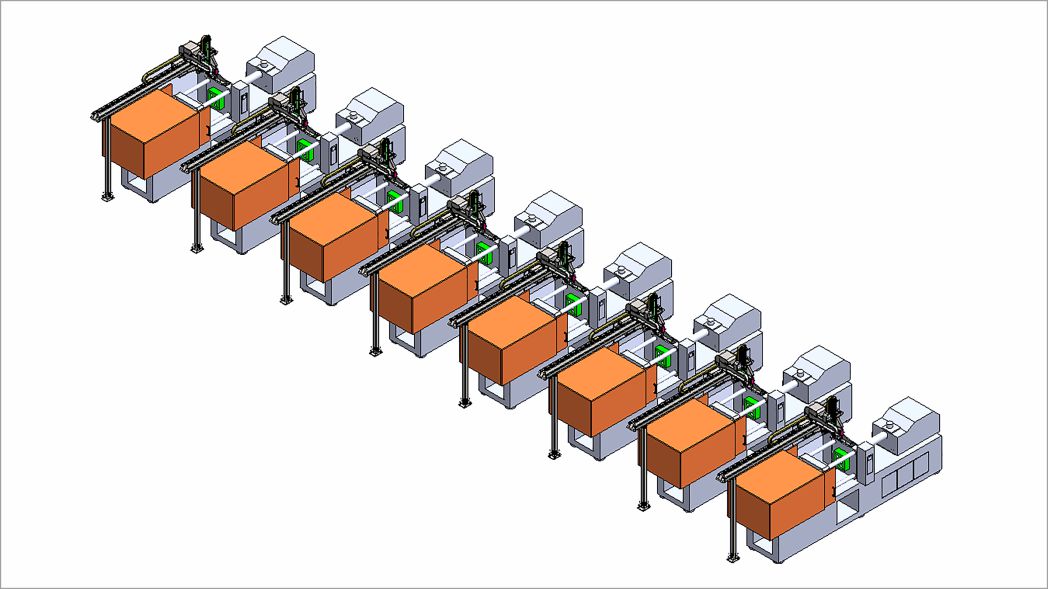

With the deepening of industrial transformation and upgrading and the weakening of demographic dividend, the application scope of industrial robots is wider and wider. Industrial robots expand the market with high load increasing rate. Injection molding manipulator is a machine specially equipped for injection production automation, which can reduce heavy manual labor and imitate part of human upper limb function, improve labor conditions and safety production. People can control them automatically so that they can carry out the production operation according to the desired delivery or handling tools. It plays an important role in improving production efficiency, stabilizing product quality, reducing reject rate, reducing production cost and enhancing competitiveness of injection molding machines.

The composition of the injection molding manipulator is generally composed of the executive system, the driving system, the control system and so on. The execution and drive system is designed to complete the normal function of the arm, and drive the operation of the mechanical parts by pneumatic or hydraulic power to achieve the function of the fetch. The control system is controlled by the drive system to make the execution system operate according to the predetermined process. Because the injection manipulator can greatly improve productivity and reduce production costs, stabilize and improve the quality of injection products, avoid losses caused by human errors. This is destined to play an increasingly important role in the production of the injection mechanic.

In recent years, the rapid development of motion control technology is mainly due to the close combination of information technology, mechanical devices and power equipment. In China, the manufacturing role clearly outlines the rapid development of machinery industry prospects for the future, in the industrial machinery automation upgrade, Shenzhen manufacturing industry as a new city, fueled by more rapid development of motion control of the market. At present, with the gradual increase of labor costs and the active transformation of industries, automated production has become an inevitable trend in the future. The widespread application of intelligent machines is an irreversible trend.

Xiao Bian learned that China intelligent machines mainly used in electronics, machinery, food, textile, clothing, footwear, furniture, logistics and other obvious repetition labor and strength, there is a certain danger of industries and enterprises, and this kind of industry technical innovation on the implementation of the most resolute automation equipment.

Although it seems that machines are gradually replacing human work, some people are unemployed, but they can liberate human beings from repetitive labor and engage in higher intelligence work. For example, the workers on the production line are trained to become the maintenance managers of the manipulator. Therefore, don't panic, the rise of a type of disappearance will have another job, we need to do is to take advantage of the times!