Shenzhen Tongcheng Automation Equipment Co., Ltd

QQ:443231019

Phone:0755-33199429

Cell phone:13823266293 Mr.Rao

18128639712 Mr.Chen

Email:

472233169@qq.com Mr.Rao

1249785244@qq.com Mr.Chen

Ministry of Foreign Trade:

Lily Mob/Wechat/WhatsAPP

/Facebook/X : +86 18772968620

Email : 2413092183@qq.com

Website:www.toolcen.com

Factory Address: No.4 Rongzhong Road, Chencun Community, Humen Town, Dongguan City, Guangdong Province, China.

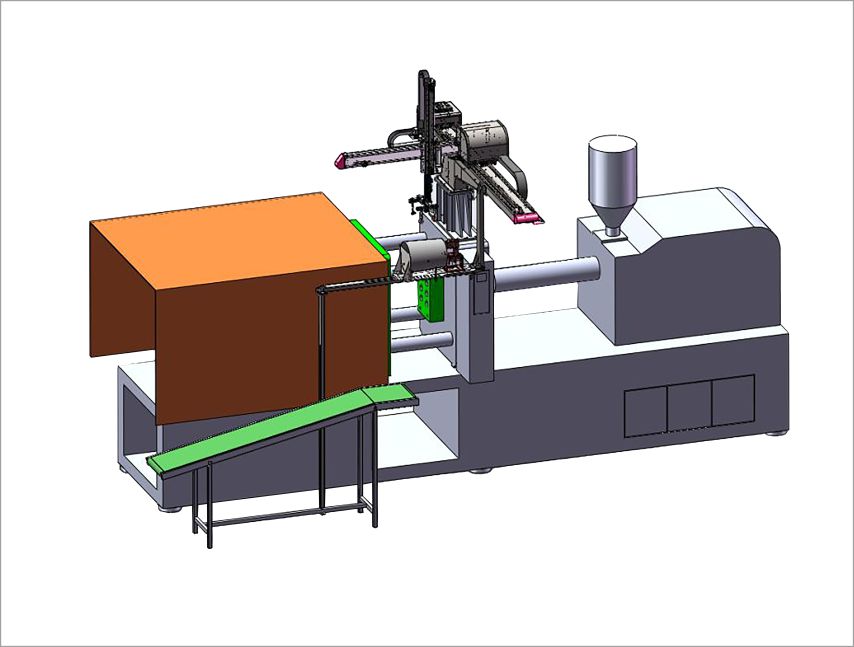

The manipulator in motion involves the rapid movement of multiple parts in different directions. In the production process, extract and mobile are not limited to vertical or parallel to the desired path movement may be very complex. Austria power company (Wittmann) manipulator model W811, W821 and W831 with B/C in the combination under the servo axis servo manipulator can provide a standard of 5 degrees of freedom, which can realize the complex motion path curve, respond to the market on small manipulator models to increase the degree of freedom of the servo drive demand.

The servo B axis of the device can increase the rotation range of the arm end tool, and the C wrist can rotate between 0-270 degrees, while the servo C axis rotates the arm end tool between 0-180 degrees. The middle position of all the rotation of the corresponding axis can be programmed to the precision of 0.01 degrees. In addition, as the manipulator model, the payload range of arm end tools and components can be achieved between the range of 3-8kg.

The optional vertical stroke of W811 manipulator is 800mm, 1000mm or 1200mm, the maximum of X axis is 620mm, and the maximum of Z axis is 2500mm. The maximum payload of the manipulator is 11 lb (5kg), which is especially suitable for the injection molding machine under the model force of 2500kN. The recoil stroke is fixed, which avoids the vibration of the hopper or mixer on the machine. A compact servo module with high dynamic performance is integrated on the manipulator, and the external control cabinet is not required. The integrated control cabinet is installed behind the horizontal axis, which saves space. It can connect to the external I/O module through the bus cable and directly control all the auxiliary devices.

Like all other W8 manipulator, W811 standard configuration has R8 control system TeachBox (with high resolution 8.5 "color LCD-VGA touch screen"), which can be used for graphics or text programming, and has great flexibility. Because of all the mighty robot are controlled by the same platform, so there is no need for training, the new program and stored procedures can be used as a template to prepare W811 manipulator. The teaching program installed in the old model can be converted into the latest version of the program online without any intervention by the operator.