Shenzhen Tongcheng Automation Equipment Co., Ltd

QQ:443231019

Phone:0755-33199429

Cell phone:13823266293 Mr.Rao

18128639712 Mr.Chen

Email:

472233169@qq.com Mr.Rao

1249785244@qq.com Mr.Chen

Ministry of Foreign Trade:

Lily Mob/Wechat/WhatsAPP

/Facebook/X : +86 18772968620

Email : 2413092183@qq.com

Website:www.toolcen.com

Factory Address: No.4 Rongzhong Road, Chencun Community, Humen Town, Dongguan City, Guangdong Province, China.

A brief discussion on the function of high speed manipulator

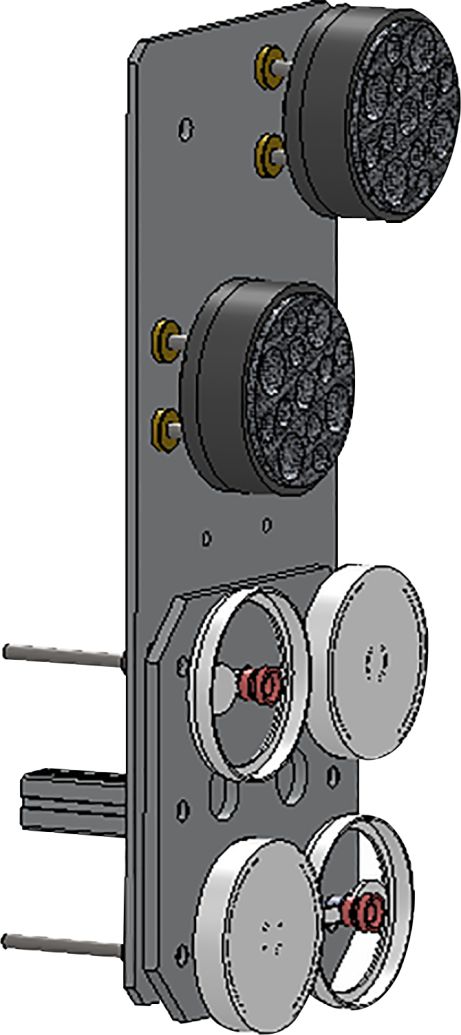

Double sectional type arm high speed manipulator with high rigiditylinear and Aluminum Alloy beam structure, special design of the belt 2x institutions with large degree of shortening of upper and lower arm of the structure on the cylinder height, just half of the stroke to reach full stroke. Besides, it can increase the speed and stability of up and down, and can match the height of the workshop.

The function of the high speed manipulator:

The electric remote control adjustment of the drawing position and stroke can save the adjustment time to increase the safety of the operation.

Up and down electric adjustment travel: up and down stroke electric remote control adjustment, save adjustment time to increase operation safety.

Horizontal axis digital control: digital set crosswise travel, can be multi point and follow the finished product, most can be put 99 points. It is used to arrange finished products.

Transverse servo motor drive: transverse axiscanuse AC servo motor drive, and adopts precision planetary gear reducer with gear rack transmission speed, accurate positioning; positioning accuracy reaches for 0.1mm. It can be applied to the precise removal of the location.

The upper and lower axle servo motor drives: the upper and lower axle of the finished arm is driven by the AC servo motor, which can move quickly, save time in mold and increase efficiency, and can set different height of external objects outside the mold. The positioning accuracy is 0.2mm.

Spout group: can set a few mold spray / spray each time / spray head can be installed on the arm or mold, the maximum can be set two groups.

Medium plate detection: to confirm the position of medium plate when the three plate die, avoid the pair arm bump the die.

The finished product of photoelectric detection: placed on the conveyor belt to prevent collision finished.

Installation of air pressure shear: can be installed on the arm or transverse end cropper.

European Union Joint: the EUROMAP12 standard joint can be configured with the ejector.

Low speed downlink of external mold: avoid crash operator.

Note: the three selection and purchase functions of the cross axis digital control, the horizontal servo motor drive and the upper and lower shaft servo motor can only be three.