Shenzhen Tongcheng Automation Equipment Co., Ltd

QQ:443231019

Phone:0755-33199429

Cell phone:13823266293 Mr.Rao

18128639712 Mr.Chen

Email:

472233169@qq.com Mr.Rao

1249785244@qq.com Mr.Chen

Ministry of Foreign Trade:

Lily Mob/Wechat/WhatsAPP

/Facebook/X : +86 18772968620

Email : 2413092183@qq.com

Website:www.toolcen.com

Factory Address: No.4 Rongzhong Road, Chencun Community, Humen Town, Dongguan City, Guangdong Province, China.

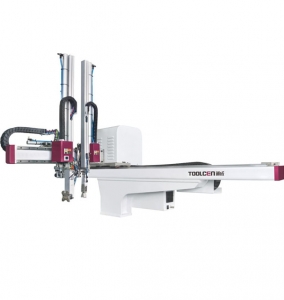

What are the categories of injection machines?Injection manipulator is a specialized equipment for injection molding production automation machinery, it can reduce the heavy manual labor, improve working conditions and safety production; some functions can imitate the human upper limb, it can automatically control it in accordance with the predetermined requirements of automated production equipment to transport products or tools to maintain the operation of the. It plays an important role in improving production efficiency, stabilizing product quality, reducing reject rate, reducing production cost and enhancing competitiveness of injection molding machine.

I, in the injection industry, the manipulator can be divided into two types according to its intelligence.

1. Basic injection molding manipulator: this type of manipulator usually includes the fixed mode program and the teaching mode program according to the production process requirements. The fixed mode program covers several standard processes for injection production and uses industrial controllers for simple, regular, and repetitive movements. The teaching model program is specially designed for the special injection molding machine, and achieves the goal of success by the orderly and safe arrangement of the basic movements.

2, intelligent robot manipulator generally include: the type of multi point memory placement, at any point, standby more freedom and other functions, generally adopts servo drive to humanoid maximum perform more complex operations, can also be equipped with advanced sensors, make it visual, tactile and thermal sleep function, make it become a very high intelligent injection molding robot.

II. Classified according to other classifications as follows:

The driving mode is divided into pneumatic, frequency conversion and servo.

According to the mechanical structure, it is divided into rotating, horizontal and side fetching.

It is divided into single and double sections according to the structure of the arm.

According to the arm, it is divided into one arm and two arms.

It is divided into the hanging arm type and the frame type according to the X axis structure.

It is divided into multiple sets of fixed programs and independent editing programs according to the different control programs.

The size of the device is moved by the arm, and it is generally increased by 100MM.